Is it possible to avoid loss of precious resources to the landfill? Only 5% of heavy metals in industrial wastewaters are recycled in Europe. With GREEN Silver we want to demonstrate that it is possible to use hazardous industrial wastewaters as a direct source of metal precursors for the synthesis of high added-value nanomaterials with an established market, completing a circular recycling/upcycling scheme with an extreme value amplification.

Current methods for the synthesis of nanomaterials rely either on laboratory grade precursors (expensive), or on industrial grade precursors (limited quality). A third, unprecetented route here explored, is the upcycling of waste grade precursors/reagents, introducing a fully circular approach to the synthesis of nanomaterials.

Current methods for treating wastewater (precipitation and flocculation, ion exchange) are based on a removal-inertization-dilution scheme that generates high volume sludges containing high quantities of metals that must be disposed in special landfills, translating into:

- unsustainable costs for the metal surface treatment industry (up to 1.200 €/ton of wastewater);

- water pollution (according to the EEA, 1 980 tons of heavy metals are released yearly in water);

- metal exit from the production cycle to the landfill.

Particular Materials has patented a continuous flow technology capable of converting aqueous solutions of metal ions into ultrafine dispersions of the corresponding oxides, metals or sulfides in water.

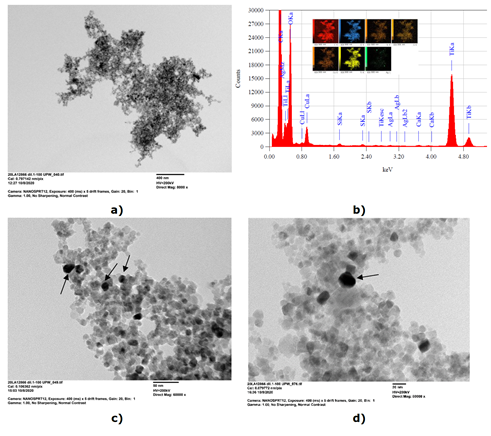

This process is originally intended to synthesize nanoparticles dispersions with an extremely fine control on size, monodispersity, degree of aggregation and composition; in 2019, thanks to the EITRM-funded Project GREEN SWAMP, Particular Materials was able to show that the commonly used precursors consisting of metals salts dissolved in water could be replaced with spent baths from the surface finishing industry, combining the production of high quality nanomaterials with the removal and recovery of heavy metals from industrial wastewaters, by means of a sustainable and fully circular process.

As compared to incumbent technologies for wastewater treatment, our process does not produce any toxic sludge destined to landfills as special waste, steeply reducing costs. In addition, it recovers valuable metals to be reintroduced in the industrial process as secondary raw materials. Finally, it enables upcycling the concept of manufacturing high-added-value compounds by directly processing metal-containing wastewaters, which is the goal of the present proposal.

After exploring several applications in GREEN SWAMP, the first targeted market application is the combined removal and recovery of silver from galvanic plating processes with the objective to obtain silver nanoparticles (AgNPs) for different application fields, directly from galvanic wastewaters while decomposing hazardous organics, like cyanides, in the resulting aqueous byproduct.

This activity has received funding from the European Institute of innovation and Technology (EIT). This body of the European Union receives support from the European Union’s Horizon 2020 research and innovation programme.